Typical examples of production aids could be

assembly fixtures

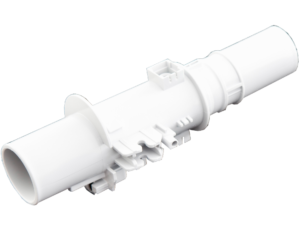

Fixtures

Production are parts that are made to speed up production. In repetitive part production, where additional machining is required for each part it is important to locate the part correctly so that machining can happen on the exact location of the part where such machining is required. Production fixtures help with this process.

Assembly fixtures have very similar function. They are used while assembling multiple parts into 1 assembly. Assembly fixtures help in locating and guiding several individual parts so that assembling the parts into a single assembly happens always at the same orientation and in the same order. This helps in maintaining uniformity for assembled parts.

Most product and assembly fixtures are machined in metal. Metal fixtures have limitations of weight as well as machining constraints. 3D printed fixtures overcome these limitations with the help of lightweight fixtures made of very strong polymers. 3D printing also can allow for shape complexity such that any constraints on machined fixtures can be overcome.

The most important part of 3D printed fixtures is that you can design a fixture on a day and have it printed and ready for testing the next day.

Stratnel has the capability to print production fixtures overnight. We have helped several customers overcome their production issues by printing fixtures. Even for our own in house printed parts, we sometimes design and print our own assembly fixtures. These fixtures help us to maintain uniformity while assembling multiple 3D printed parts.

Sacrificial patterns

In investment casting, sacrificial patterns are used for creating ceramic shells and after the shells are baked, the inner material, usually wax, is melted away. However wax patterns need molds which are expensive and not very well suited for low volume needs. 3D printed investment casting patterns work well in these cases. The patterns are burnt away during the baking process leaving a ceramic shell with the negative of the pattern inside. 3D printed investment casting patterns are being used effectively by a large number of foundries. Such patterns mean savings on mold cost. The patterns also enable the cast parts to have a much better finish as compared to wax patterns. This in turn brings in further savings in the form of lesser machining costs.

Stratnel has supplied 1000’s of patterns to satisfied foundry customers all over India.