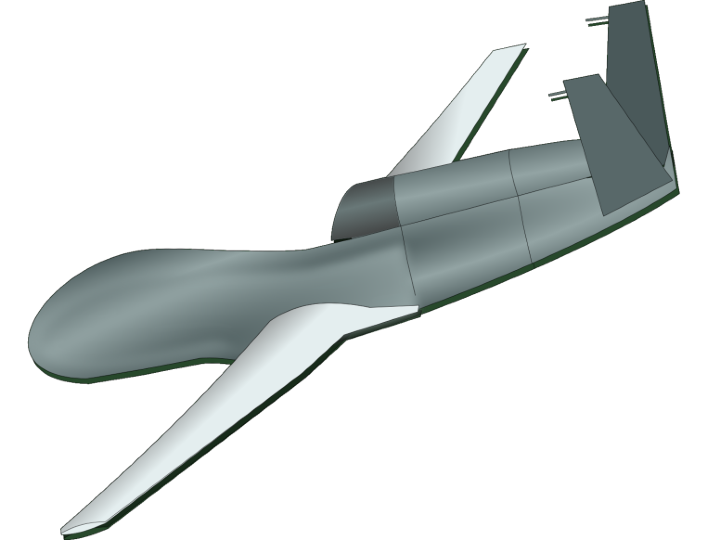

The aerospace industry has very high adoption in 3D printing and has invested heavily in this technology. Here are some examples of how the aerospace industry has taken advantage of additive manufacturing:

1

Weight reduction

Every gram saved in the weight of an aircraft helps to improve fuel efficiency. It is also possible to attain cost savings by efficient design. Even if the cost of making a part using additive manufacturing is more than through traditional means, the weight reduction offered by AM more than compensates for the increased costs with long lasting fuel savings and better efficiency of the aircraft.

2

Efficiency improvement

By combining several parts together into a single part, it is possible to reduce the number of components in an aircraft. This helps to improve the reliability of the aircraft, reduce assembly costs, increase part efficiency and reduce inventory costs.

3

Inventory reduction

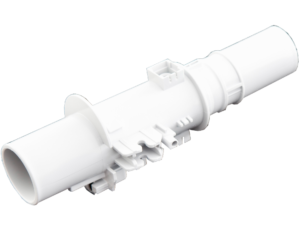

The fuel nozzles used by aircraft is a very good example of inventory reduction. GE claims that their leap fuel nozzle has helped to reduce inventory costs by 95% and have lowered component costs by 30%.

4

Legacy spares

It is now possible to make spare parts for aircraft which have been in use for several years. Even if spare part manufacture for these old aircraft has tapered off, AM helps in making custom parts from any design and thus help prolong the life of aircraft as well as improve reliability.

5

Improved wear properties

Using AM it is now possible to make crucial wear parts using specialty metals such that the wear rate of the parts is slowed down. This improves the life of the parts and also increases reliability, while bringing down overall replacement costs. Stratnel makes parts in high performance plastics such as Nylon, Nylon CRF, PEEK, PEKK, Ultem, PPSU, etc.

6

Supply chain optimization

Instead of maintaining a huge inventory of spare parts, it is now possible to make parts on demand. This helps to not only reduce inventory holding costs. It also reduces freight costs and outsourcing admin costs. A 3D printer can be installed virtually anywhere. So multiple service centers with 3D printers can now churn out part on demand, helping large fleet owners to optimize heavily on their supply chain.

Stratnel sells various models of Industrial 3D printers and will help you to go through the learning curve. We provide installation and maintenance support. We can also hand hold you and optimize your print parts for the first few weeks or months that you need, in order to familiarize yourself with the 3D printing process.

Don’t forget to check out our the Printers section of our website.