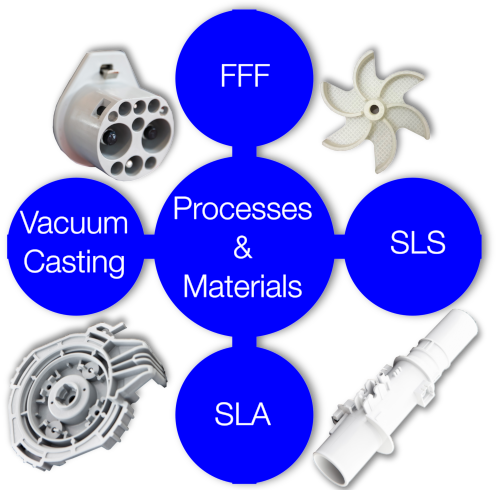

FDM/FFF

Fused Deposition Modeling also known as Fused Filament Fabrication (FFF) uses filaments that are fused in multiple layers to create complex geometry parts. This is the most common method of 3D printing and is typically used for prototyping and design validation.

Stratnel offers the following materials for FDM printing

Standard Thermo plastic materials

- PLA

- PETG

- ABS

High Performance Engineering Plastics

- Polycarbonate

- PEEK

- Ultem

- Nylon (PA)

- PETGCFR

- PACFR

- ASA

- PCABS, etc.

Thermoplastic Elastomers

TPE: By its nature, TPE is elastic and flexible. Used in applications that require a higher degree of flexibility.

SLA

Stereolithography or SLA is used for printing parts with very fine features that less than 1mm in size.

For the SLA process, Stratnel offers several material choices:

Thermo Set Plastic Materials

Thermo set plastic materials become rigid in an irreversible manner. These are materials that are meant for a single use and cannot be reused. Stratnel offers the following thermo set plastic resins for SLA printing.

- Grey resin

- Tough resin

- Clear resin (translucent)

- Castable resins, etc.

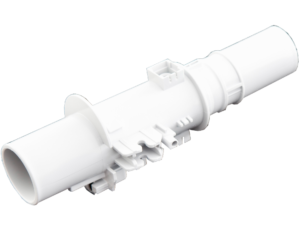

SLS

Selective Laser Sintering: SLS is the process by which polymer powder is sintered to form complex shapes. The advantage of SLS process is that small parts with fine features can be produced with good finish.

This is the preferred method for bulk quantities of end use parts.

- PA12

- PA11 and

- TPU

Vacuum Casting

Vacuum Casting is the process by which a positive of the part is made as a master. Silicone moulds which form the negative of the parts are made using the master. Polymer resin is then poured into the silicone moulds in vacuum condition in order to produce the final part. Vacuum cast parts come with good definition and smooth finish. The typical layer lines found in 3D printed parts is not present in this method. Vacuum casting is an ideal method for producing a few hundred parts for pilot production.

Stratnel offers the following resin for Vacuum Casting: Synthene PR 700.

The natural colour of this material is black. If the use case needs different colours, Stratnel also offers painting services for painting the parts with your colour of choice.