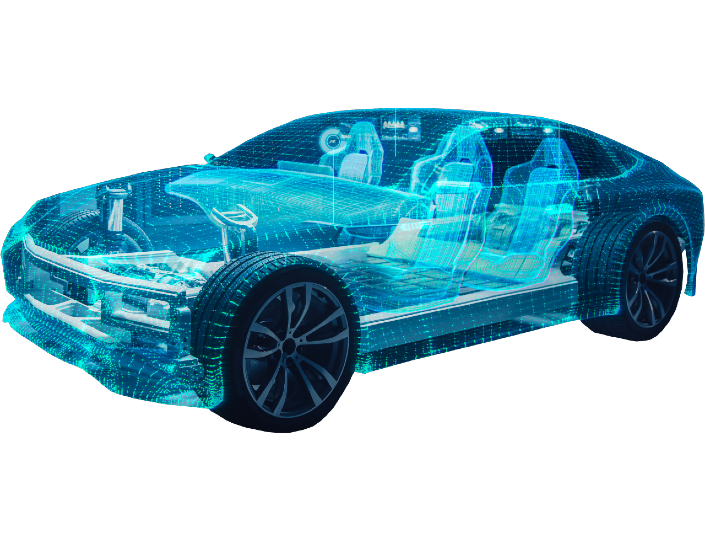

Stratnel has been involved with several customers for additive manufacturing applications, especially in the Electric Vehicle (EV) segment. The EV segment is still evolving and there are several tens of startups trying to become unicorns. Stratnel works closely with several of these customers to help them speed up their prototyping and pilot production requirements.

Design

VALIDATION

At this stage, typically, automotive companies work on early stage designs. These designs have to undergo several trials and iterations before the final product is ready for pilot production. During the design validation stage, several parameters of the part such as form and fit, functional, environmental and wear resistance characteristics are tested aggressively and changes made as required for product requirement. Stratnel helps these customers by 3D printing a few parts that can be tested in each iteration.

Pilot

PRODUCTION

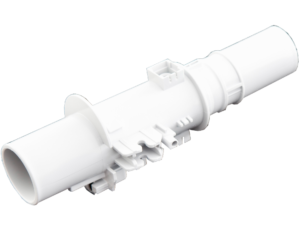

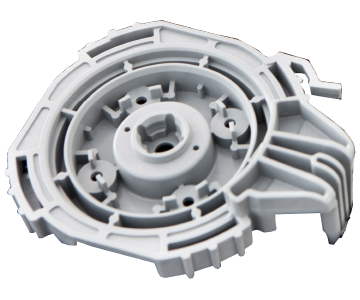

During pilot production, users would like to make a few hundred to a few thousand parts to fit into actual vehicles and test run them to make sure all parts are working as expected. During this period, a lot of rigorous testing gets done under as adverse conditions as possible. Making plastic parts in limited numbers rules out injection molding, as mold costs can be prohibitive.

Stratnel offers two solutions for limited number of parts. We can either vacuum cast these parts or get them done through SLS. Which process to use will depend on part geometry, finish needed and part functionality. We will make appropriate recommendation based on the user requirements and also suggest changes based on manufacturability in future for millions of these parts.