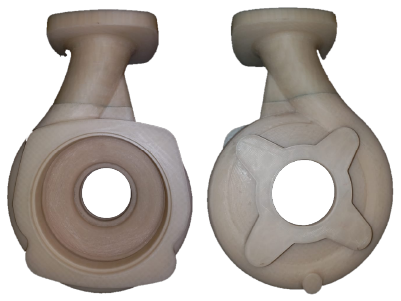

Investment casting involves pouring molten metal into wax patterns coated with ceramic slurry. The first part of this process is to make moulds into which wax gets injected to make wax patterns. The important part of investment casting is that the wax patterns are single use. During the process of making these parts, the pattern melts away and gets destroyed.

Investment casting or lost wax casting provides certain advantages over sand casting. Investment casting is more expensive than sand casting. But, the process provides thinner sections. It has better dimensional tolerance and finish. This method is better for casting complex, intricate and fine metal objects. It has a lot of adoption in the jewellery industry.

Tooling costs can be high for investment casting. A mould with fine details is used for injecting wax. This generates the wax patterns which are then coated with slurry. When baked at high temperatures, the slurry hardens and the wax melts. This creates a pattern for pouring metal.

The mould for making wax patterns is expensive, has long lead times and needs process control.

Investment

Casting

Additive

Manufacturing

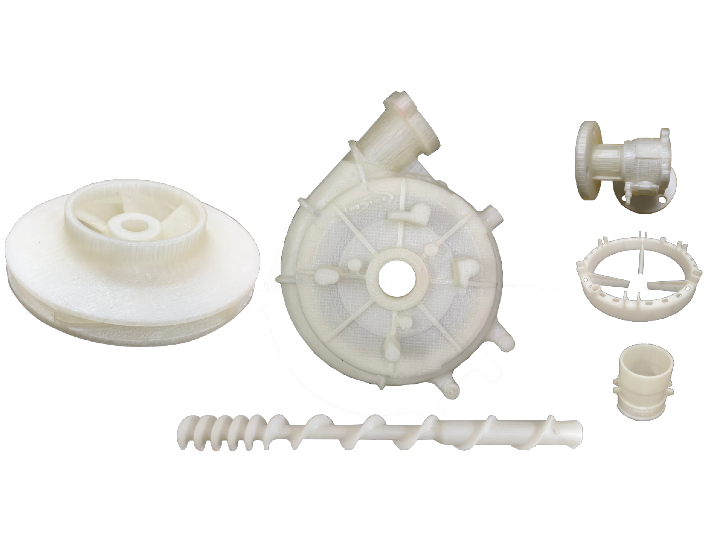

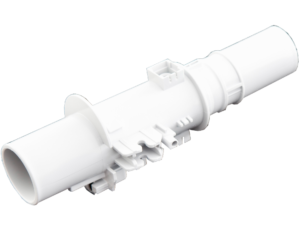

Additive manufacturing provides several advantages for Investment casting. The biggest advantage is the fact that one can do away with moulds. Additive manufacturing can straight away print patterns with fine details.

The mould making costs can be very high. So Investment Casting can be very expensive at low volumes. 3D printed patterns may cost more than wax patterns. But there is no need for moulds with 3D printing. So at low volumes, additive manufacturing can bring in economies.

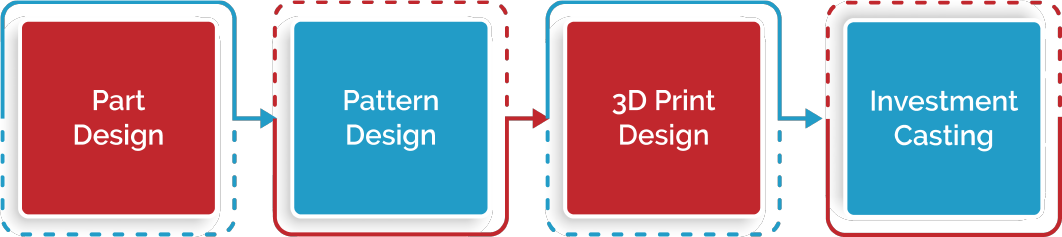

The chart below shows how the process flow of

investment casting can be improved.

Investment Casting Traditional Flow

Investment Casting 3D printing flow

The other advantages that derive from using additive manufacturing for investment casting include:

No Mold cost

Reduce Lead time

Cast complex parts

Reduce no. of process steps

Increase Yield

Combine multiple parts

Stratnel Investment Casting Patterns

Stratnel is a well established reputed supplier of Investment Casting patterns to several large and leading foundries, as well as pump and valve makers, in India. Our patterns have been well received and have helped our customers in being successful. Here are some testimonials from our customers: