We will be happy to give you a free demo.

Find out how our products can work for you. Our team is trained to offer you the best solution for the job.

SCHEDULE DEMOHigh strength all steel chassis

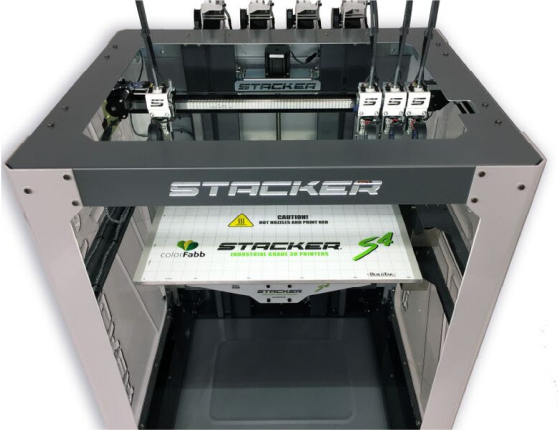

The key to high-performance 3D printing is having a chassis that is beyond rigid while also absorbing unwanted vibrations. This is where design and engineering cross paths. The Stacker chassis is formed with special AC Servo driven presses that are unmatched in precision repeatability, as well as maintaining the integrity of the steel during the bending process. Most parts are formed on the most advanced and modern punch presses by Trumpf. All parts are powder coated, not painted. Powder coating is much more environmentally friendly, and much more durable.

Precision built

All Stacker printers are built around a massive high precision custom building jig. In fact, the S4 chassis and building jig were designed together. That’s how important it is to get your things right. Essentially, the building jig ensures the X/Y plane is in the correct relationship to the Z plane. This is a lot easier said than done, and most other printers have no way of gauging this short of making a test print.

Made in the U.S.A.

A true Industrial Grade 3D printer should be assembled by a highly skilled workforce. The Stacker 3D printers are exclusively made in the U.S.A. The skill sets and technology needed to assemble precision high-quality 3D printers is abundantly available in the US and Stacker sticks to the proud tradition of manufacturing in the USA. This means high quality, reliability, and workmanship.

Print large parts with the Stacker S4

.embed-container { position: relative; padding-bottom: 56.25%; height: 0; overflow: hidden; max-width: 100%; } .embed-container iframe, .embed-container object, .embed-container embed { position: absolute; top: 0; left: 0; width: 100%; height: 100%; }

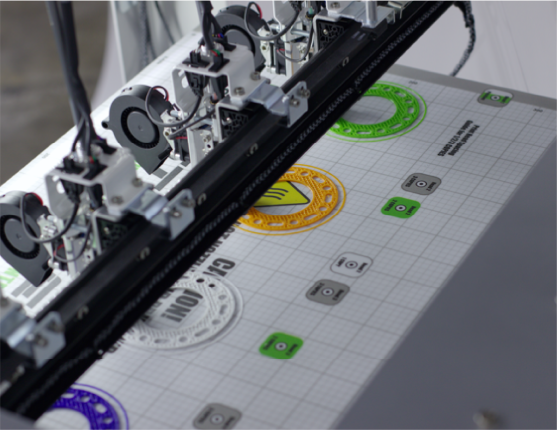

Print up to 4 parts at once

.embed-container { position: relative; padding-bottom: 56.25%; height: 0; overflow: hidden; max-width: 100%; } .embed-container iframe, .embed-container object, .embed-container embed { position: absolute; top: 0; left: 0; width: 100%; height: 100%; }

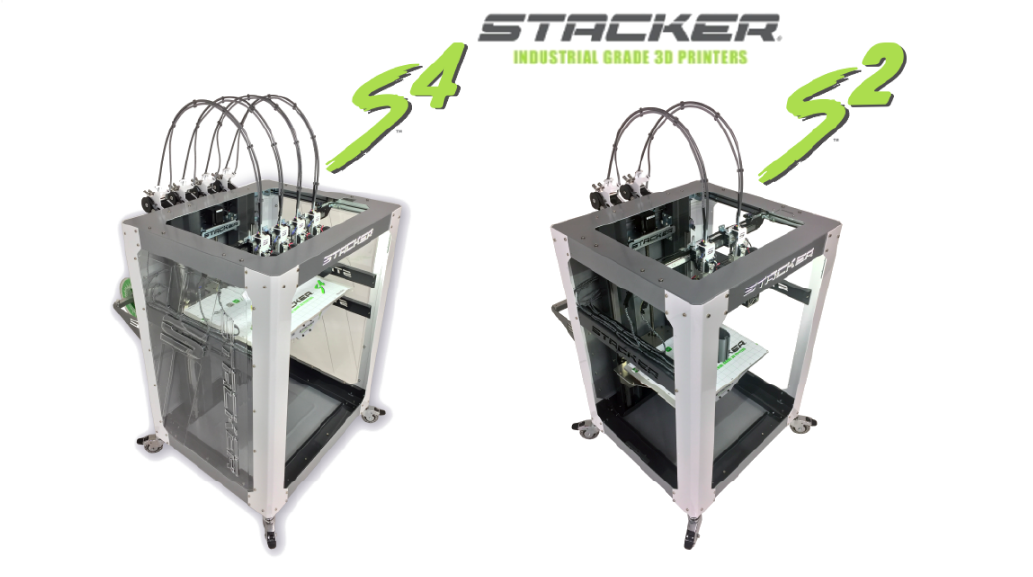

Model comparison

Contact us for a free demo

STACKER S4

4 parts/build

Large print volume 510mm (X), 360mm (Y), 650mm (Z)

Optimized for high tech composite filaments like carbon fiber

Custom designed high

temperature hot ends for smooth and reliable printing over wide

range of materials

Change nozzle size easily from 0.25mm to 1.00mm

Strong and rigid steel

frame construction

Precision ground heated

aluminum print bed comes with

our custom BuildTak bed coating

Integrated full locking casters

Industrial duty components

Includes Simplify3D Slicing Software

STACKER S2

2 parts/build

Large print volume 390mm (X), 315mm (Y), 525mm (Z)

Optimized for high tech composite filaments like carbon fiber

Custom designed high

temperature hot ends for smooth

and reliable printing over wide

range of materials

Change nozzle size easily from 0.25mm to 1.00mm

Strong and rigid steel frame construction

Precision ground heated

aluminum print bed comes with

our custom BuildTak bed coating

Integrated full locking casters

Industrial duty components

Includes Simplify3D Slicing Software