Top 9 reasons to adopt 3D printing for manufacturing

Thousands of companies world over are deploying additive manufacturing processes through 3D printing services. This helps them to address challenging engineering problems as well as open up new business opportunities. We examine 3 broad segments, which get impacted with the adoption of 3D printing.

Design can take on more complexity

Product designers are now challenged with the necessity to take on a new avatar, relearning all they learnt so far.

1. Manufacturability made easy by reducing process steps

The traditional manufacturing process, for example, of a sub-assembly or in layman’s terms a part for a product, involves taking into account “Design for Assembly” (DFA) and “Design for Manufacturing”(DFM). Any major design acceptance involves thoroughly evaluating DFA and DFM. With 3D printing, the traditional “design->tool->mold->prototype->tool->mold-> prototype->make->assemble” model is thrown out. The new paradigm is about “design-print-prototype-test-tool-mold-make”. Since most of the tooling and mold requirements are postponed until the final iteration, the leadtime and costs of prototyping get reduced by an order of magnitude.

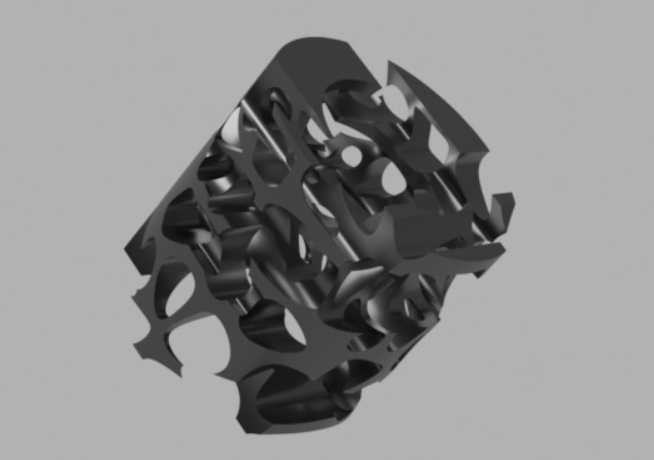

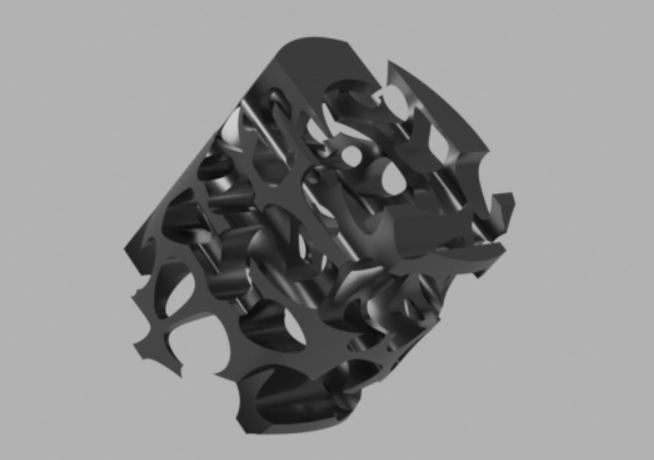

2. Shape complexity not an issue

The limitations of subtractive manufacturing techniques restrained the pre-3dp designers from taking advantage of complex shapes for improving product performance parameters such as structural, thermal, optical, conductive, mechanical, etc. With 3dp, designers can address this issue, whether it is for ducts for wiring/lubrication, screw holes or any other complex cavity inside the shape.

3. Designs can be optimized for performance

An optimized design should be able to provide the best measurable performance under given manufacturing constraints. Design optimization algorithms typically analyze the relationship between different variables using linear and non-linear programming techniques. 3D printing is able to remove several of these constraints such that design optimization is much faster, as it gives several more options to designers.

Manufacturing can be more agile

Manufacturing takes on a new dimension by being empowered to try designs that have not been possible to be manufactured before.

4. Weight Reduction is not just for aircraft

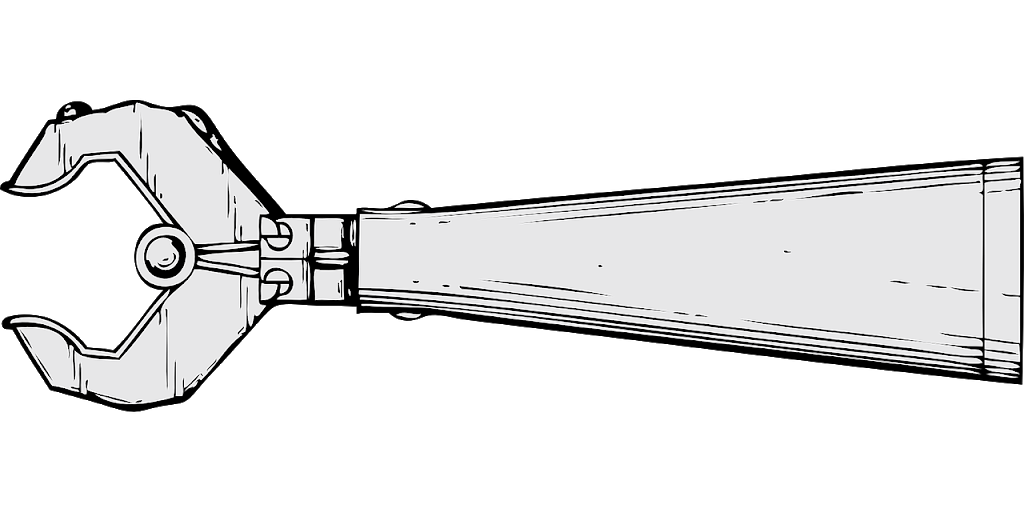

Several industries can benefit from weight reduction and 3D printing can enable weight reduction by controlling “fill” parameters. Example – Weight reduction in End of Arm Fixture (EOAF) can reduce a robot’s payload requirements.

Reducing the weight of the EOAF enables the assembly process to use robots with lower weight handling capability. 3D printed components with reduced weights is a possible way to reduce weights of robotic arms. Also lower payload robots cost less.

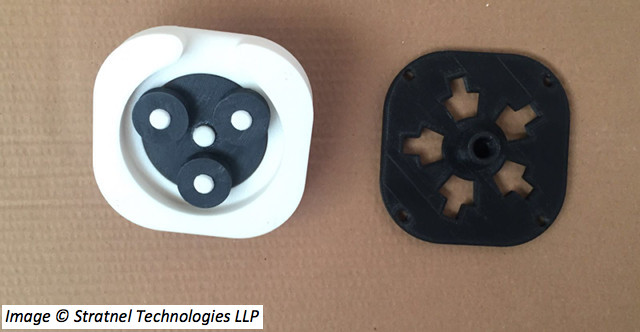

5. Reliability of fixtures with design integration

Subtractive manufacturing may require several process steps for products with inner cavities – including machining, drilling, etc. 3D printing takes away several of these multiple steps in one fell swoop and enables the company to design and print the whole product with cavities and all in one step. Integration of multiple process steps as part of an intrinsic design enhances the reliability of the product and also brings in more design options.

6. Low cycle times to catch windows of opportunity

This is one of the best advantages of 3d printing. It gives the NPI team the ability to iterate multiple times to test design validity since 3D printing has short cycle times and does not need expensive tools and molds to be ordered. The entire prototyping cycle is shortened and helps in giving a working product to marketing and sales teams, so that they can catch windows of opportunity.

7. Material mix and match

Where parts have multiple materials or materials of different colors, traditional manufacturing has to design them as separate parts and assemble them inline. 3D printing enables the designer to think more creatively and design a product with multiple materials, colors and shapes and to print it in a single process step.

Marketing can take on more challanges

Marketing and Sales can take on new challenges when their upstream processes use 3D printing – opportunities that they could not address earlier.

8. Manage short life cycle products

Luxury product trends are changing. High fashion products have very short life cycles. Product models change very fast and there are infinite variations. 3D printing allows quick design changes and customization.

9. Low volume runs and Test Marketing

In subtractive manufacturing, regardless of the volume of the products, necessary costs have to incurred for molds and tooling. 3D printing takes away these onerous costs and enables manufacturers to address opportunities with small volumes. Designers would therefore have to be ingenious enough to adopt 3d printing and work with a revised workflow in order to be able to let their company be successful.