How to save measurement time with custom 3D printed fixtures

Have you been asked to do a Cpk analysis and spent hours of time measuring each part in your sample set?

There are less painful, and more reliable ways to do this sort of thing.

We’ll show you how we improve reliability and save hours of measurement time with 3D printed fixtures.

Cpk is an index (a simple number) which measures how close a process is running to its specification limits, relative to the natural variability of the process. The larger the index, the less likely it is that any item will be outside the specs.

— Neil Polhemus

Traditional fixture design is expensive

Traditional fixture design, manufacturing, and assembly pieces and assembling them could be quite cumbersome and time consuming.

Repeated manual measurements are risky

To get an accurate measure of CP or Cpk for your manufacturing process, you need to make multiple repeat measurements of parts in your sample size.

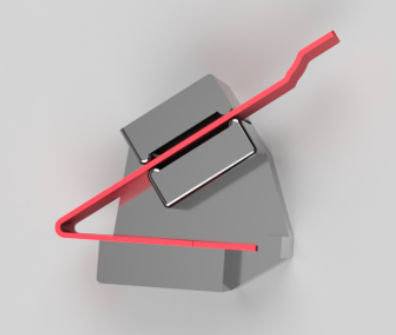

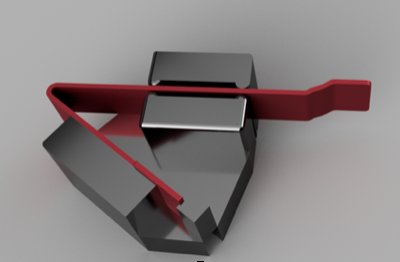

Take this stamped part that needs to be measured, for example.

Stamped Part:1

Stamped Part:2

Sample size, 32 nos.

What you do typically to measure is like this:

- For each sample, align it against a fixture.

- Measure each side carefully.

This traditional alignment process constantly nags your mind with repeatability doubts.

Design and print your own fixtures

Delicate pieces, like this stamped part, are measured easily with fixtures. Fixtures take away both the problems of alignment time and repeatability doubts.

Example

Here’s a fixture we designed internally at Stratnel for this part.

This 3D printed fixture can be made in a matter of hours and 1/4 the cost of a traditionally manufactured one.

More on this, in the next part of this series.